Your Cart is Empty

FREE SHIPPING FOR USA

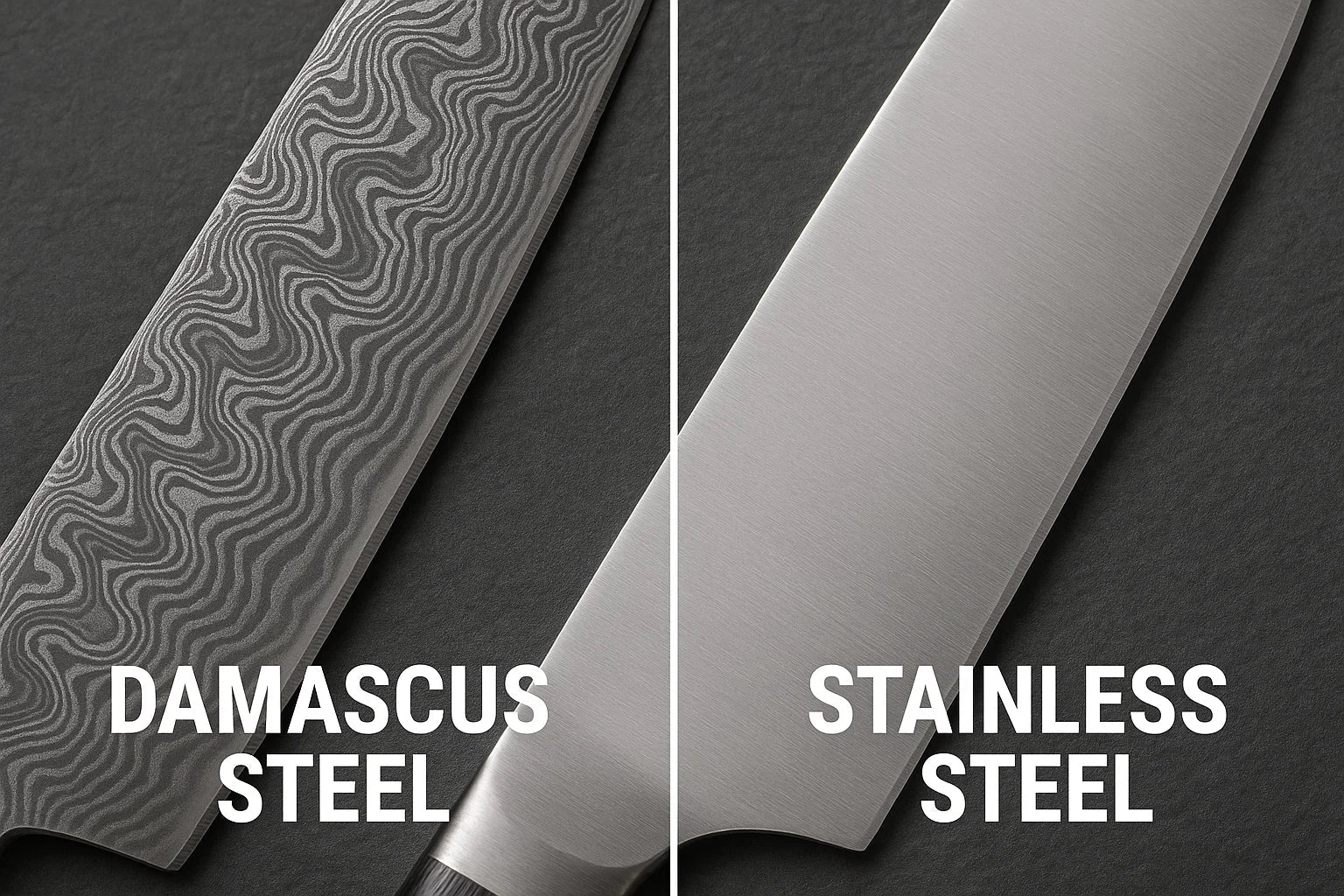

When choosing a high-quality knife, two popular contenders dominate the conversation: Damascus steel knives and stainless steel knives.

While both materials can deliver excellent performance, they differ significantly in composition, appearance, maintenance needs, and long-term value.

In this guide, we’ll compare Damascus and stainless steel across all key factors so you can choose the right blade for your needs — whether you’re a collector, chef, outdoorsman, or casual user.

Entity definition: Traditionally, Damascus steel referred to blades made from wootz steel originating in India and the Middle East, famous for their wavy, water-like patterns.

Modern meaning: Today, most Damascus knives are made via pattern welding — layering high-carbon steels (often 15N20 and 1095) and forging them together to create intricate patterns.

Attributes: Exceptional edge retention, unique visual patterns, higher hardness (often HRC 58–62).

Entity definition: An alloy of iron, carbon, and at least 10.5% chromium, which forms a passive oxide layer that resists corrosion.

Common types: 420HC, VG-10, AUS-8, 440C, and S35VN.

Attributes: High corrosion resistance, easy maintenance, smooth polished finish.

| Feature | Damascus Steel | Stainless Steel |

|---|---|---|

| Appearance | Distinctive wavy patterns, each blade unique | Plain polished or brushed finish |

| Edge Retention | Excellent — holds a sharp edge longer | Good to excellent depending on alloy |

| Corrosion Resistance | Lower than stainless — requires oiling | Very high, minimal maintenance |

| Hardness (HRC) | Typically 58–62 | Typically 55–60 |

| Sharpening Difficulty | Slightly more effort due to hardness | Easier to sharpen |

| Price Range | Mid to high, due to forging process | Wide range, from budget to premium |

| Collector Value | High — artistry and craftsmanship | Moderate — mostly functional value |

Pros

Exceptional aesthetics — no two blades look alike

Superior hardness for long edge retention

High craftsmanship value and collectability

Often hand-forged for better balance

Cons

Requires more maintenance (oiling after use)

More expensive than mass-produced stainless knives

Can be faked — need to verify authenticity

Pros

Very low maintenance

Affordable options available

Resistant to rust even in humid environments

Widely available in many styles

Cons

Lacks unique artistic patterning

Edge retention varies by alloy

Less collectible appeal

For Daily Kitchen Use: If you want easy maintenance, stainless steel may suit you better — especially for busy kitchens.

For Collectors & Enthusiasts: Damascus steel offers artistry, history, and unique appeal.

For Outdoor Use: Stainless steel resists rust better in wet conditions, but Damascus can perform exceptionally with proper care.

For Gift Giving: Damascus steel’s patterns make it a standout choice for special occasions.

Damascus Steel: Clean immediately after use, dry thoroughly, and apply light mineral oil to prevent rust.

Stainless Steel: Wash and dry after use — oiling is optional.

Related reading:

At Jun Knives, we craft both full tang Damascus Knives and to meet different needs.

If you value artistry, tradition, and unmatched edge retention, explore our Damascus Knives Collection.

Q: Is Damascus steel stronger than stainless steel?

A: Damascus often has higher hardness (HRC 58–62) and can maintain a sharper edge longer, but stainless offers superior rust resistance.

Q: Can Damascus steel be stainless?

A: Yes, some modern Damascus knives use stainless alloys in the pattern weld, offering both beauty and rust resistance.

Q: Which is better for the kitchen — Damascus or stainless?

A: For professional chefs who want the best cutting performance and aesthetics, Damascus is excellent; for casual cooks, stainless is easier to maintain.

Q: Why are Damascus knives more expensive?

A: The forging process, layered steel construction, and artistry increase labor time and uniqueness, raising the price.

Q: How do I prevent rust on Damascus steel?

A: Clean promptly, dry thoroughly, and apply light oil after use, especially in humid climates.