Your Cart is Empty

FREE SHIPPING FOR USA

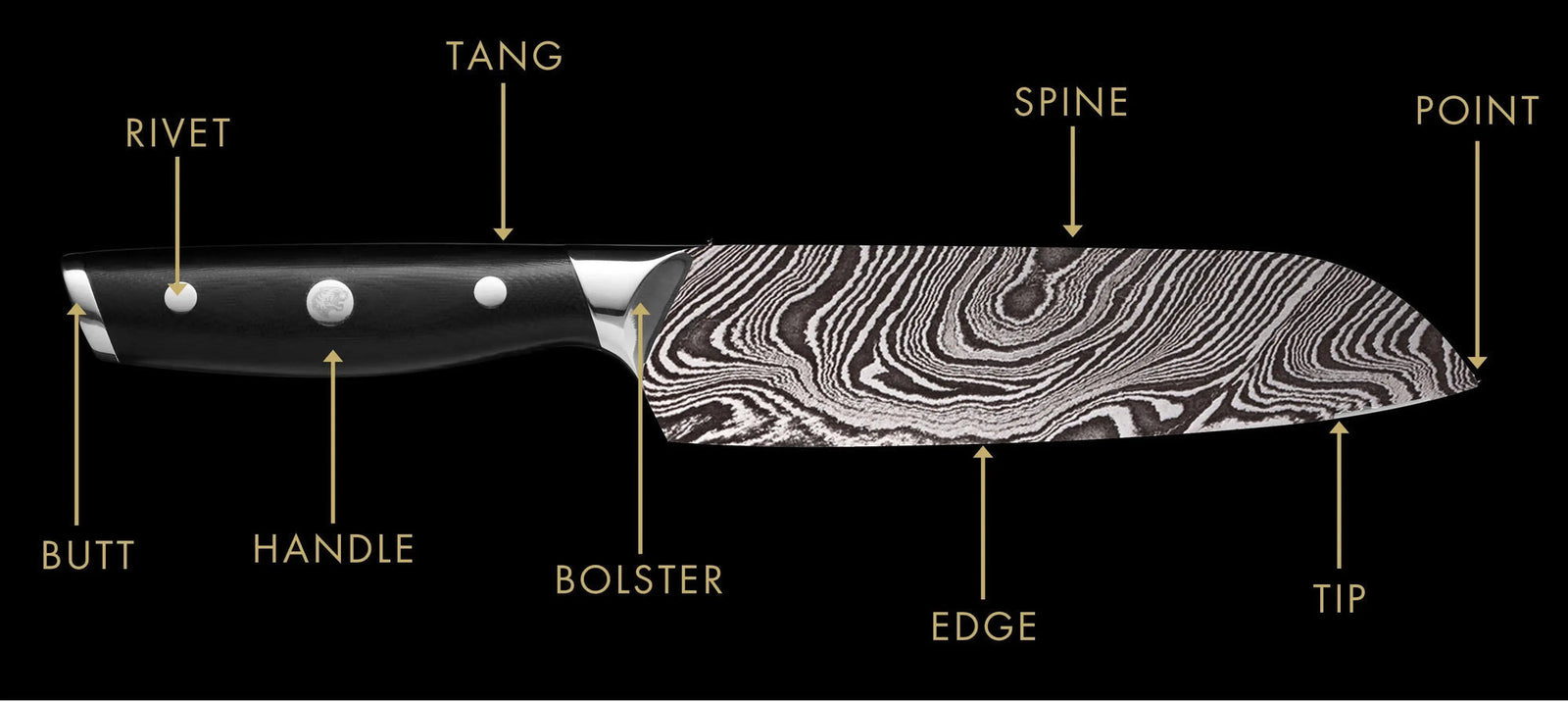

Damascus steel knives are the perfect blend of tradition, art, and performance. Known for their wave-like patterns, razor-sharp edges, and durable multi-layered construction, Damascus blades are more than just cutting tools — they’re a reflection of heritage and craftsmanship.

At Jun Knives, every blade is hand-forged using traditional techniques, often with over 365 layers of steel, delivering both aesthetic appeal and peak functionality. In this article, we’ll walk you through the anatomy of a Damascus blade — and what makes it one of the most sought-after knives in the world.

Damascus blades are crafted by combining two or more steels, often high-carbon steel and stainless steel. This combination results in a blade that offers:

Extreme hardness for sharpness

Toughness to resist breakage

Corrosion resistance for longevity

At Jun Knives, we focus on steel quality and traditional craftsmanship to ensure each blade performs under pressure — and looks stunning while doing so.

The most recognizable trait of Damascus knives is their layered steel construction. This involves:

Repeatedly folding and hammering layers of steel

Creating intricate, organic wave-like patterns

This process produces:

Enhanced structural integrity

Improved shock absorption

Unique visual character — no two blades are the same

Every Damascus pattern tells a story. Some of the most iconic designs include:

Twist Pattern – Spiraling designs across the blade

Ladder Pattern – Structured, geometric steps

Raindrop Pattern – Circular ripple-like motifs

Feather Pattern – Complex, mirrored feather visuals

Mosaic Pattern – Artistic, symmetrical blocks

Each pattern is a result of the forger’s choices — from twist speed to billet arrangement.

After forging, Damascus blades are etched with acid to highlight their layered design. This etching process:

Brings out the contrast between hard and soft steel layers

Enhances the blade’s aesthetic appeal

Preserves the authentic craftsmanship

Etching is not just for looks — it also reveals the quality and density of the layering beneath.

At the center of a Damascus blade lies the core steel, which is usually high-carbon for maximum edge retention. This core ensures:

Precision cutting

Long-lasting sharpness

Strong edge durability

Surrounding the core are the Damascus cladding layers, which:

Add visual flair

Improve flexibility and toughness

Provide corrosion resistance

This san-mai (three-part) construction is key to performance and aesthetics.

Damascus knives are celebrated for their razor-like edge, capable of slicing with minimal effort. The combination of hard-core steel and softer outer layers ensures:

Excellent edge sharpness

Superior edge retention

Less frequent sharpening

The spine of the blade — the thick top edge — adds:

Rigidity and balance

Structural strength

Finger rest for precision work

The tang is the part of the blade that extends into the handle. Jun Knives uses full tang construction for:

Better balance

Increased strength

Safer handling

Full tang blades outperform partial tang in durability and are a hallmark of professional-grade knives.

A great Damascus blade deserves an equally beautiful and functional handle. We use materials such as:

Exotic hardwoods (walnut, rosewood, olive wood)

Bone and antler (for rustic, traditional appeal)

Micarta or stabilized resin (for durability)

Each handle is shaped and finished by hand, offering both aesthetic harmony and ergonomic comfort.

Comfort matters — especially for long cutting sessions. Our knife handles are:

Ergonomically contoured

Non-slip even when wet

Balanced for precision and ease of use

A well-designed handle enhances control and reduces hand fatigue.

One of the standout features offered at Jun Knives is custom blade engraving. Whether it's initials, a logo, or a symbolic design, engraving your Damascus knife adds:

Personal significance

Collector value

A thoughtful gift element

Engraving is done with care to preserve blade strength and pattern integrity. It makes your knife truly one of a kind.

Each Damascus knife deserves proper storage. We offer handcrafted leather sheaths designed specifically for our blades.

Benefits include:

Blade protection during travel or storage

Enhanced aesthetic presentation

Durability and wear resistance from natural leather

Secure snap-closure or belt-loop designs for outdoor use

Unlike plastic or synthetic cases, leather sheaths age gracefully and add a rugged, classic look to your knife.

To ensure long-term performance and appearance:

Use a whetstone to sharpen (avoid cheap pull sharpeners)

Always hand wash with mild soap, rinse, and dry immediately

Avoid twisting, prying, or hacking with the blade

Store in a dry place: leather sheath, knife block, or magnetic strip

Apply food-safe oil periodically to protect the blade from rust

The anatomy of a Damascus blade is a perfect blend of performance and elegance — from its layered construction and acid-etched designs to its core steel, engraving, and custom handle.

Whether you’re a professional chef, outdoorsman, or collector, a Damascus knife from Jun Knives offers:

Unmatched cutting ability

Timeless beauty

Personal and functional value

These aren’t just knives — they’re hand-forged legacies you can pass down through generations.